3D Printing is an additive manufacturing process that uses a digital design to create a physical product. The major 3D Printing technologies, and materials available, are based on the principle of creating a solid three-dimensional physical object by adding layers of material, one layer at a time.

How does 3D Printing work?

As with any form of artistic creation, we begin with a blueprint that guides us in creating the desired end product. Similarly, any 3D Print begins as a digital design, divided into countless horizontal layers before being sent to the 3D Printer, which begins to carefully print our product – layer by lay- er!

Based on the technology available, the printing process uses a variety of materials, ranging from plastics to rubber, sandstone, metals and alloys – with more and more options appearing on the market every year!

What caused today’s 3D Printing hype?

In 2009, expiry of the patent for fused deposition modelling (FDM), possibly the most common 3D Printing technology, resulted in 3D Printing moving beyond the industrial manufacturing space. As more manufacturers turned towards this technology, the price of having your own 3D Printer plummeted. Technology that once cost over hundreds of thousands of dollars was now available for less than $2000, marking the rise of the 3D Printing era.

As expected, the world has seen a steady rise in 3D Printer sales, and has been growing ever since. We currently have over 3,00,000 consumer 3D Printers in the world, and this figure shows no sign of slowing down as we discover more technological innovations in the years to come.

The Pros and Cons of 3D Printing

The rapidly evolving technology of 3D Printing comes with a vast collection of benefits, but also presents its own unique set of challenges in manufacturing.

Pros of 3D Printing

• Ability to create complex designs

• Customisation of each and every detail

• Lower Fixed Costs, with no need for tools & hardware • Rapid Response in Prototyping

• Less Wastage from Production

Cons of 3D Printing

• Higher costs for large production facilities

• Less choice in Materials, Colours, Finish etc. • Limited Endurance & Strength

• Less Precision & Control during process

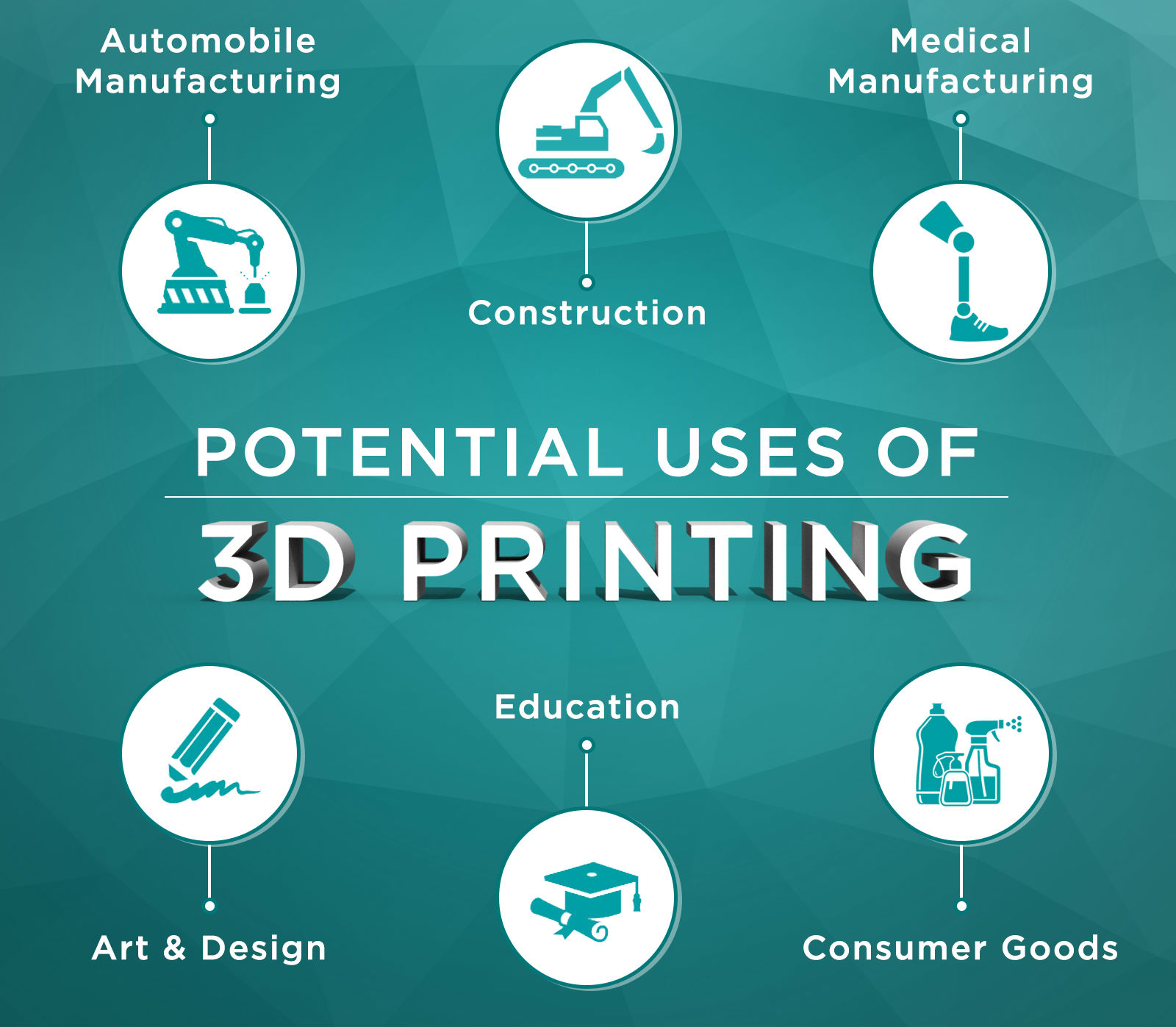

Medical Manufacturing

Prosthetic Manufacturers

Doctors

Dentists

Construction

Improved Infrastructure in Developing Areas

Automobile Manufacturing

Motor Vehicle Manufacturers

Aerospace Manufacturers

Art & Design

Engineers

Architects

Product Designers

Interior Decorators

Consumer Goods

Clothing Manufacturers

Home Utensil Manufacturers

Comfort & Leisure Goods

Education

Learning Tool for Infants,

Students, Professionals